Crushing

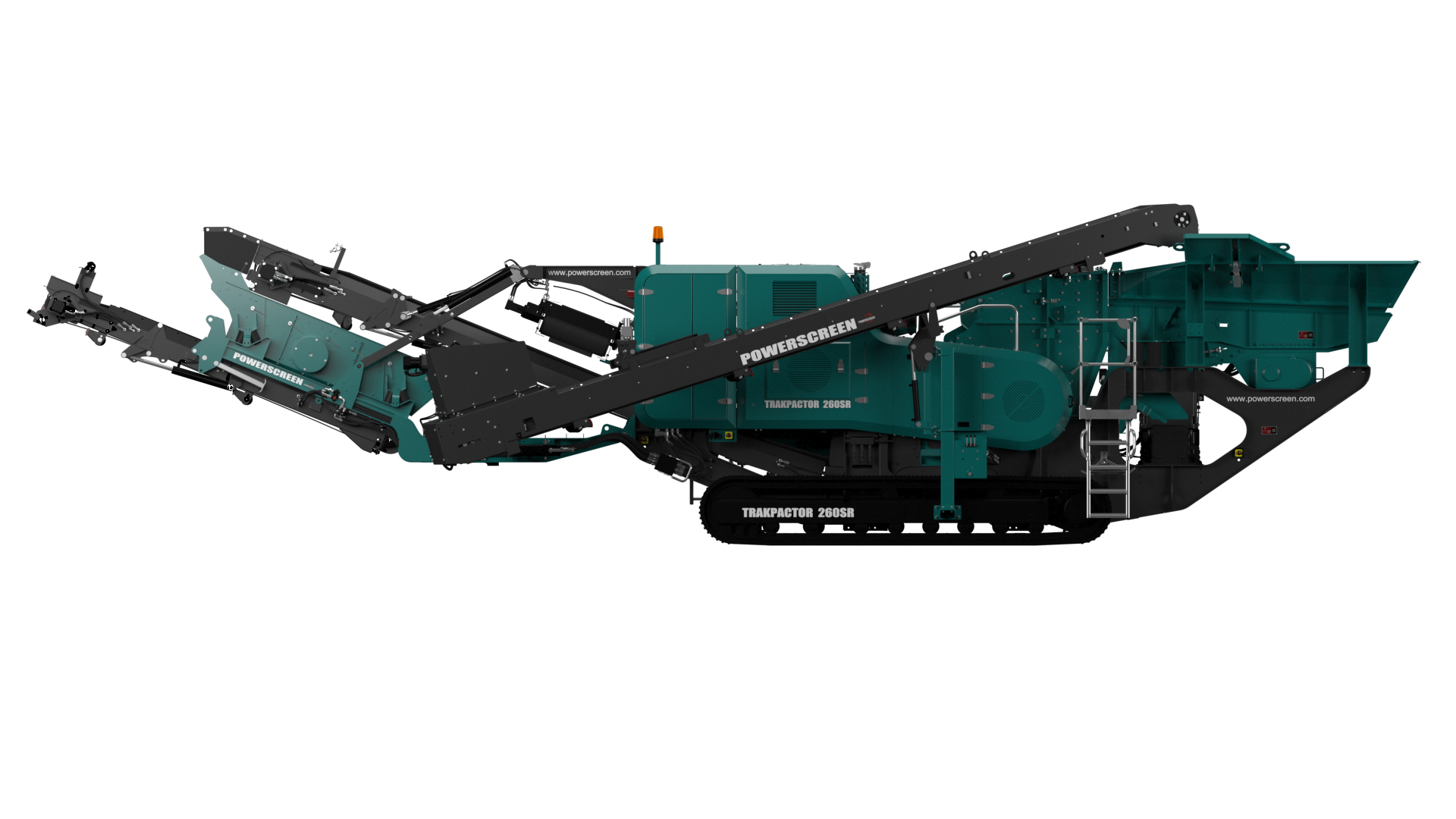

Trakpactor 260SR

The Powerscreen ® Trakpactor 260SR Horizontal Shaft Impactor, is a highly compact tracked crusher designed to offer both excellent reduction & high consistency of product yield. A post-screen system and recirculating conveyor allows oversize material to be passed back to the crusher for further sizing.

The Powerscreen ® Trakpactor 260SR is designed mainly for the recycling & demolition markets & is an ideal contract machine due to its compact design & mobility. A quick-detach single deck post-screen system allows the machine to convert to a standard Trakpactor 260 in minutes.

go back

go back