Crushing

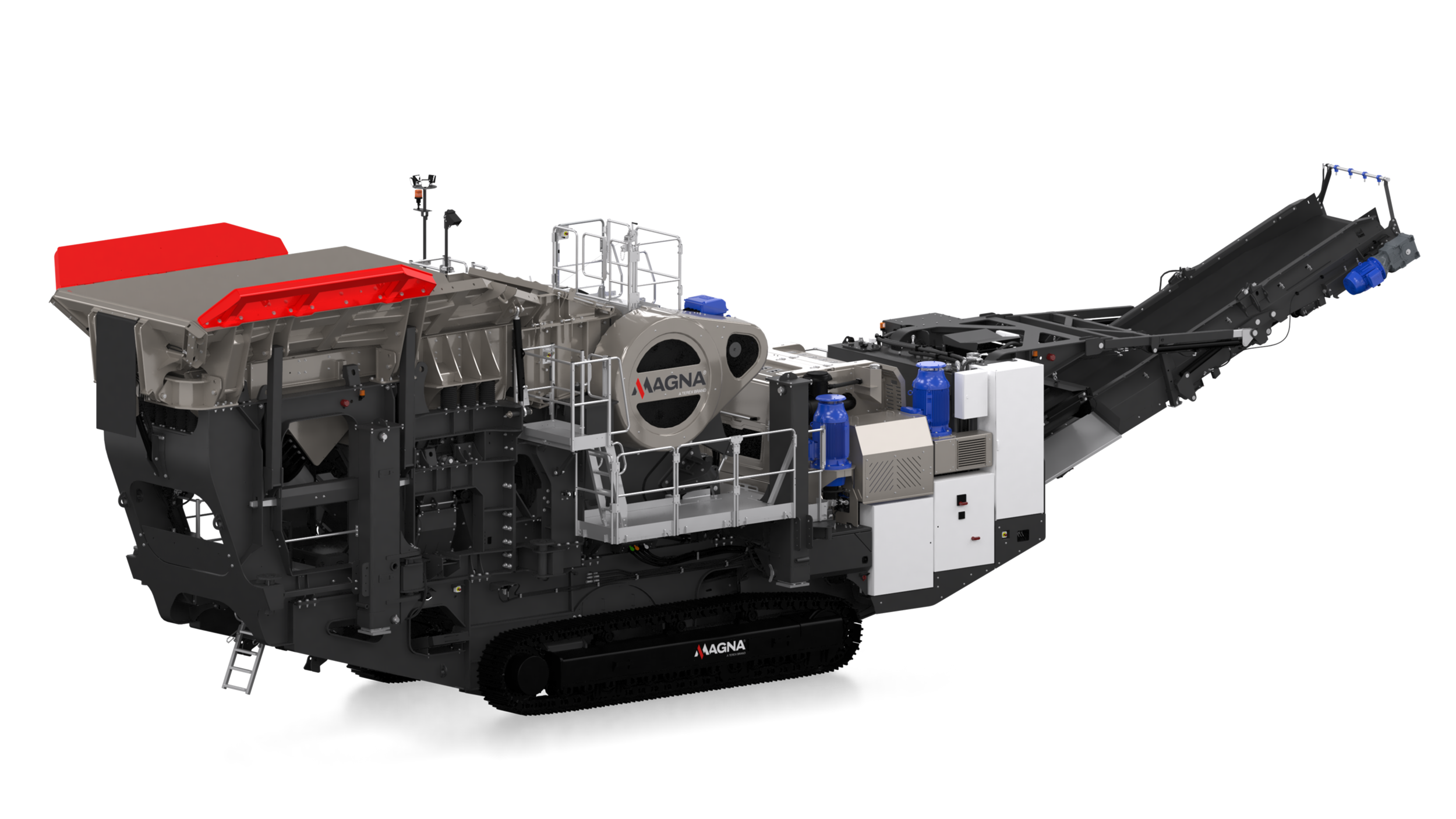

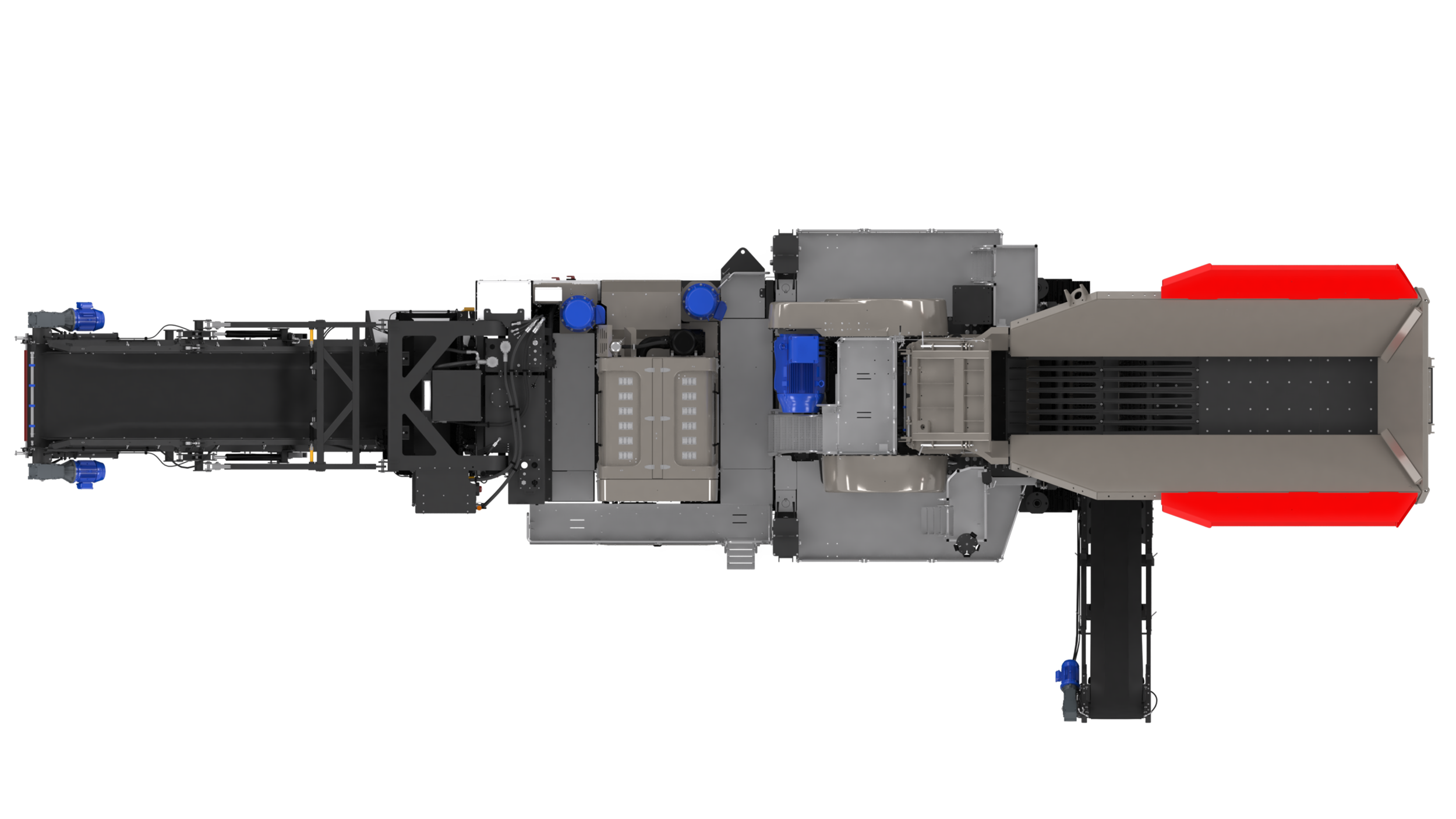

MT130J

The MAGNA MT130J hybrid mobile jaw crusher has been developed for large-scale quarry and mining operations. The machine can operate as standalone primary crusher or integrated into a mobile or static crushing and screening plant.

The MT130J can be powered either by the onboard genset powerpack configuration or connected to an external power source. Both power options provide operators with significant power, servicing and maintenance cost savings in direct comparison to a diesel/ hydraulic powered plant.

go back

go back