Screening

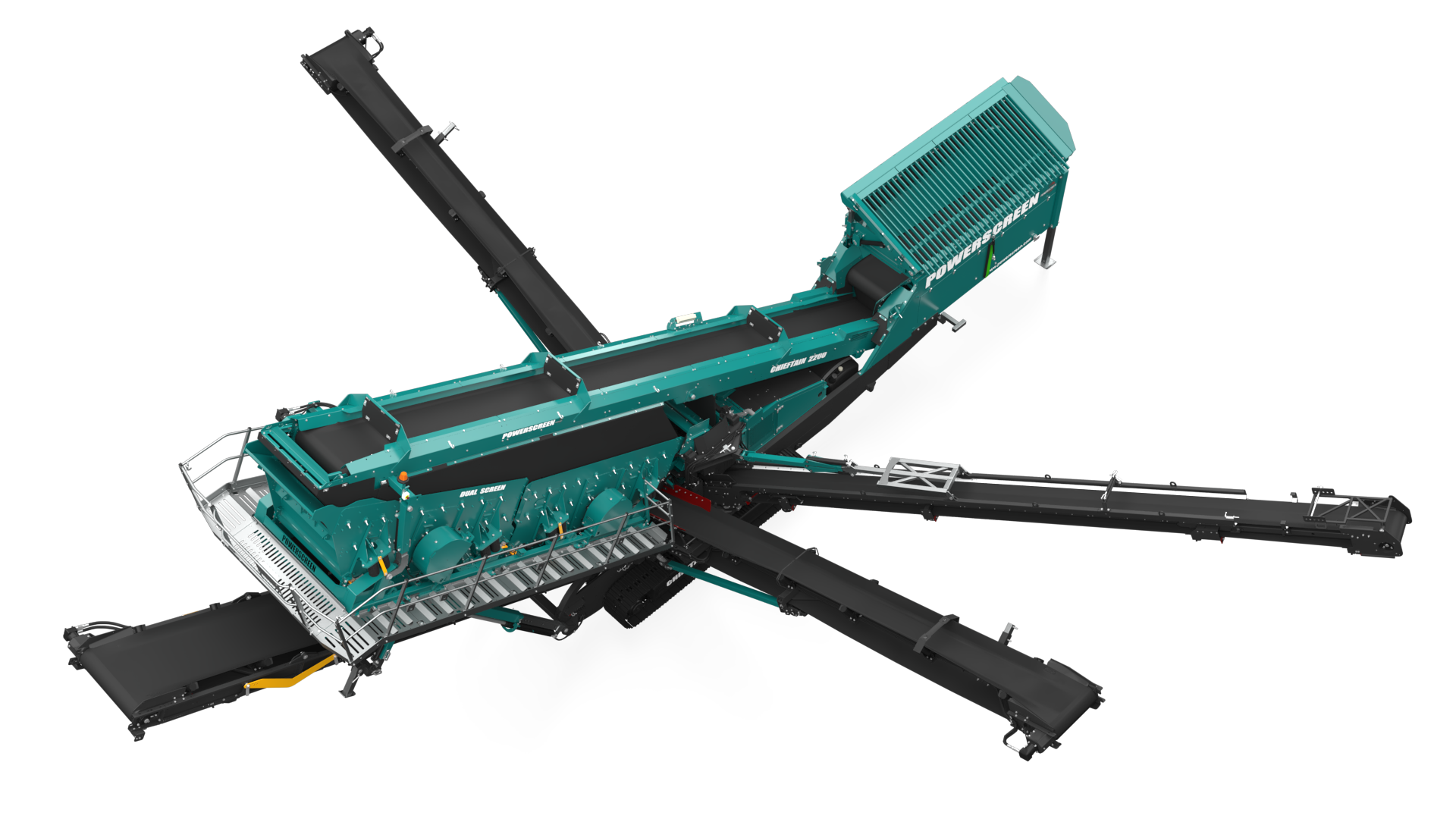

Chieftain 2200 3 Deck

The Powerscreen Chieftain 2200 3 deck is designed for operators who require large volumes of high specification products with maximum versatility. Its patent pending drive system which allows switching between 2 and 4 bearing with bolt-on parts. By splitting up into two individual boxes, the Chieftain 2200 3 deck is able to run aggressively without the constraints of a larger box.

go back

go back