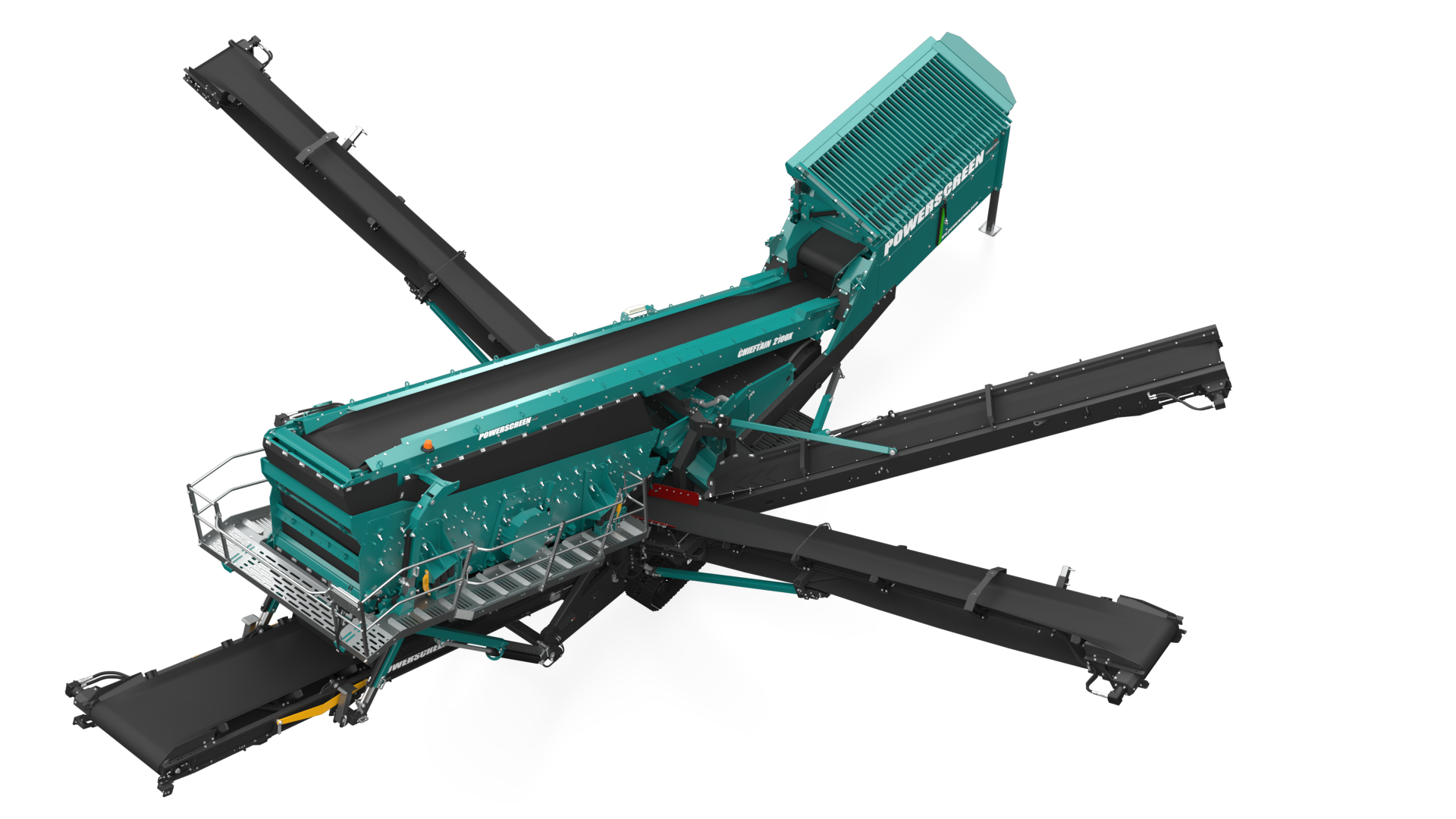

Chieftain 2100X 3 Deck

he Powerscreen Chieftain 2100X is designed for medium to large scale operators who require large volumes of high specification product. The screenbox can be finely tuned to suit the application with its adjustable stroke, angle and speed. Featuring quick set up times and maximum mobility, low ground pressure tracks – an operator can have the unit operational in minutes.

Serviceability is a priority on the Chieftain 2100X with its transverse power unit arrangement and a drop down fines conveyor facility to aid bottom deck mesh changes. The 3 deck Chieftain 2100X allows the operator to create a fourth saleable product. Alternatively, the hydraulic auxiliary conveyor can easily feed the oversize back into the hopper of a another unit for further screening or crushing.

go back

go back