Screening

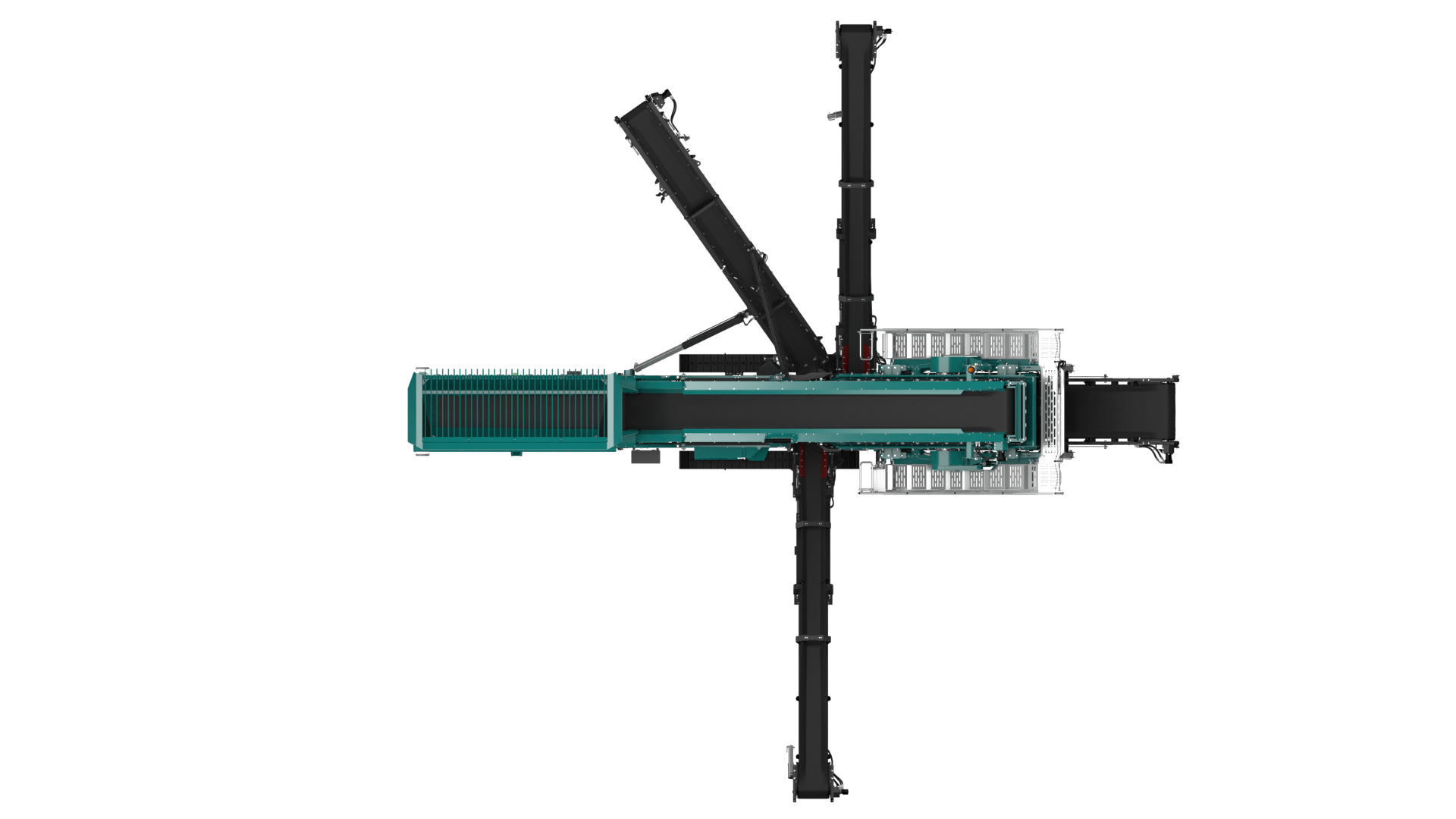

Chieftain 1700X 3 Deck

The Powerscreen® Chieftain 1700X 3 Deck allows users to add an additional deck to the 1700 to create a fourth product. User benefits include a quick set-up time, drop down tail conveyor and screen mesh access system to aid screen media changes and a transverse powerunit arrangement to simplify servicing. Features a radio controlled tipping grid and heavy duty single shaft screenbox with adjustable stroke, angle, and speed.

go back

go back