Crushing

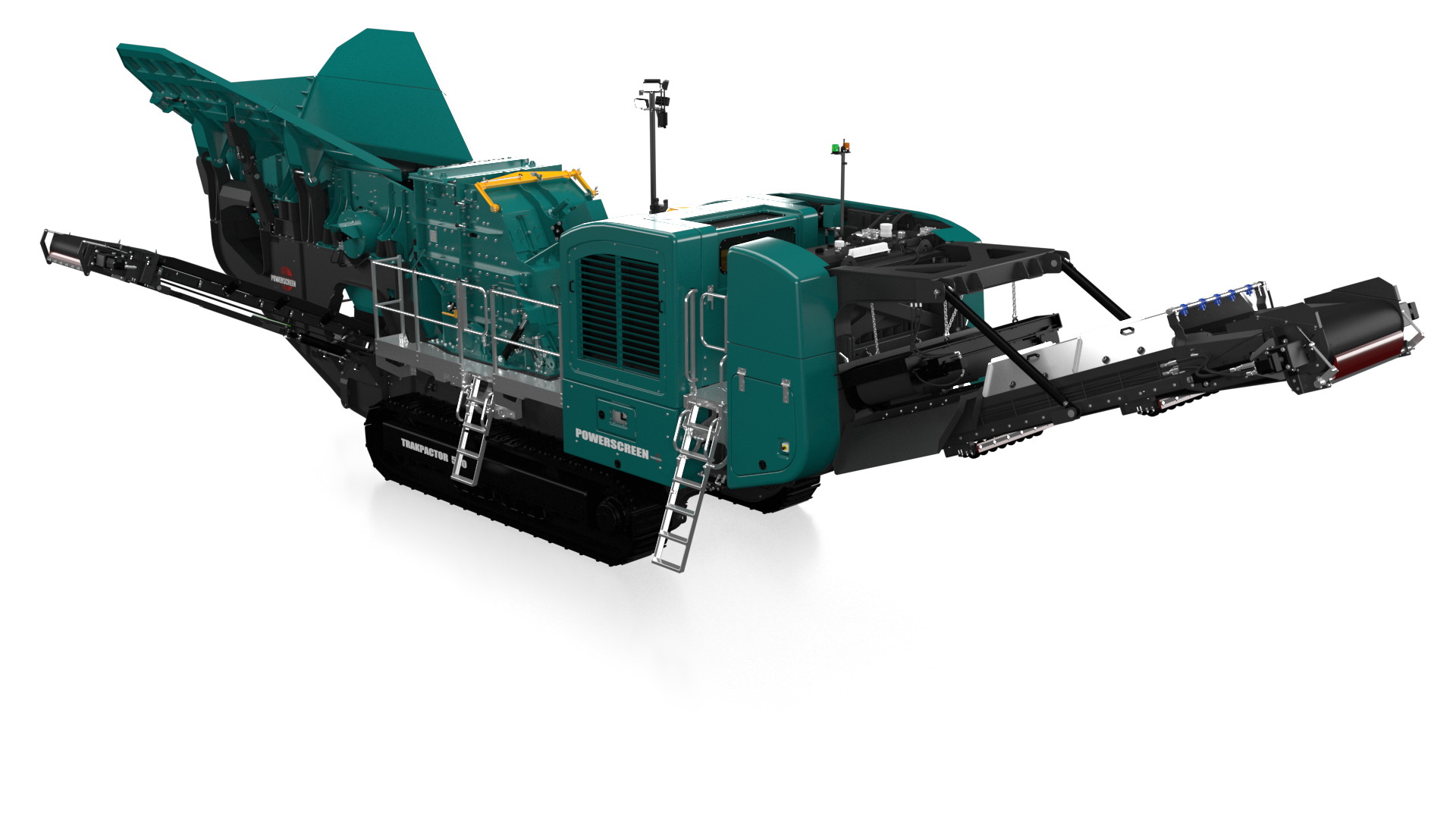

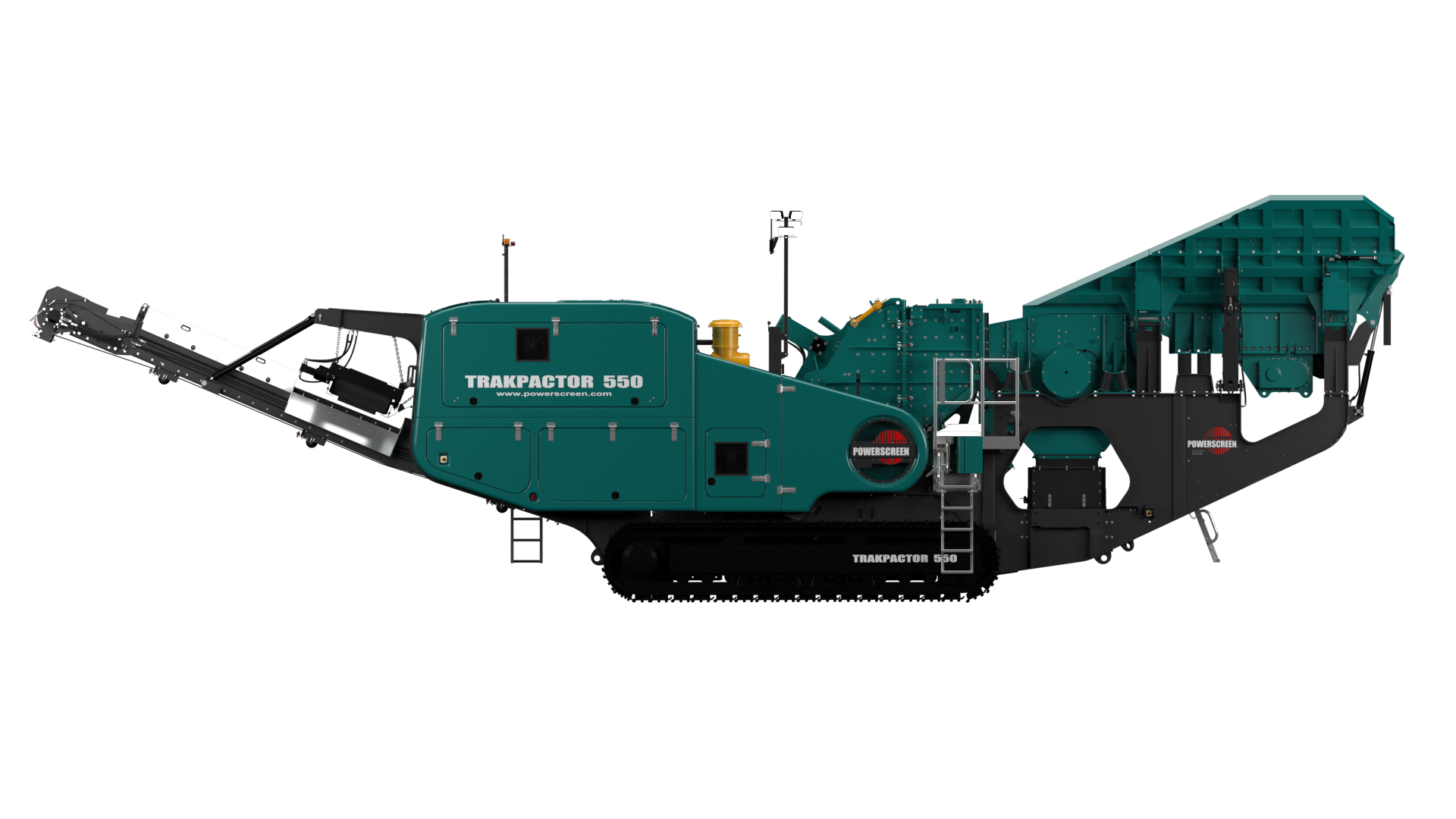

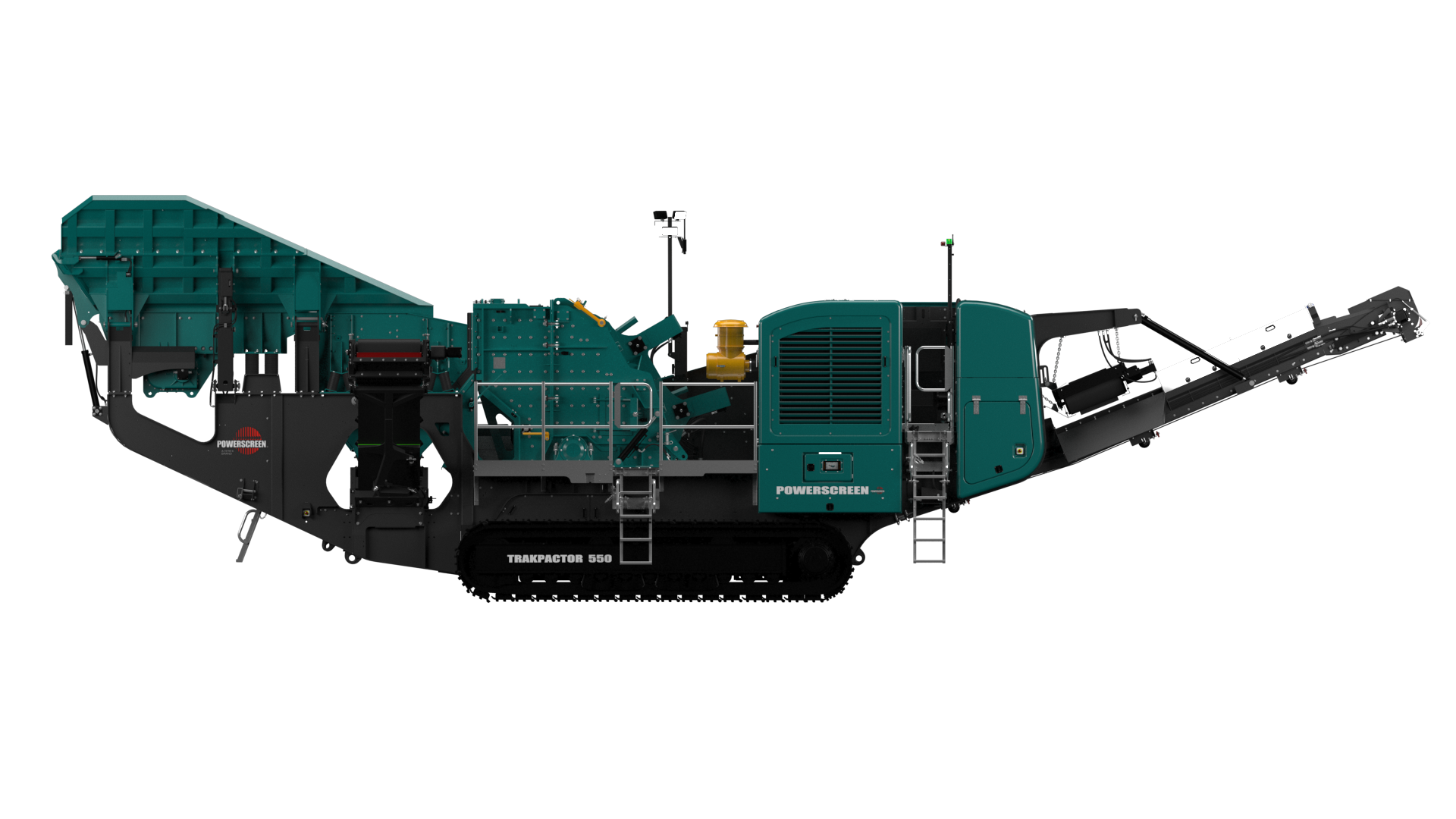

Trakpactor 550

The Powerscreen ® Trakpactor 550’s robust impact chamber features a twin apron, 4 bar rotor design, with hydraulic release aprons, hydraulic setting adjustment, hydraulic crusher overload & is driven directly off the engine via clutch for optimum fuel economy. Next crushed material passes; either over the independent under pan feeder & modular product conveyor, or directly onto the full length conveyor, both conveyors feature a raise/lower facility to aid clearance of rebar in the event of a blockage.

The plant has been designed with ease of maintenance in mind, hydraulic banks, battery access and control valves are at eye level to make setup and operation much easier.

go back

go back