Screening

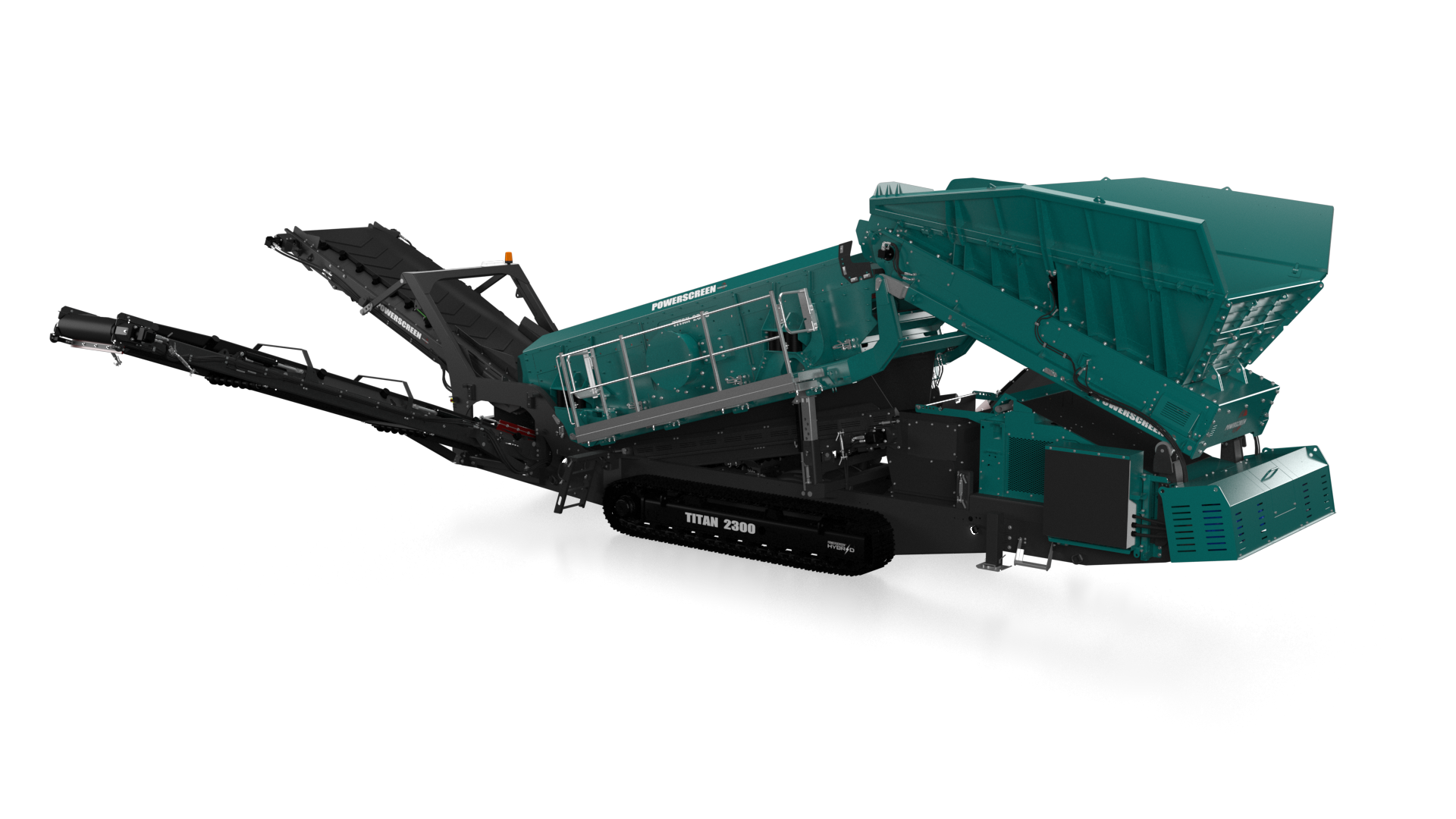

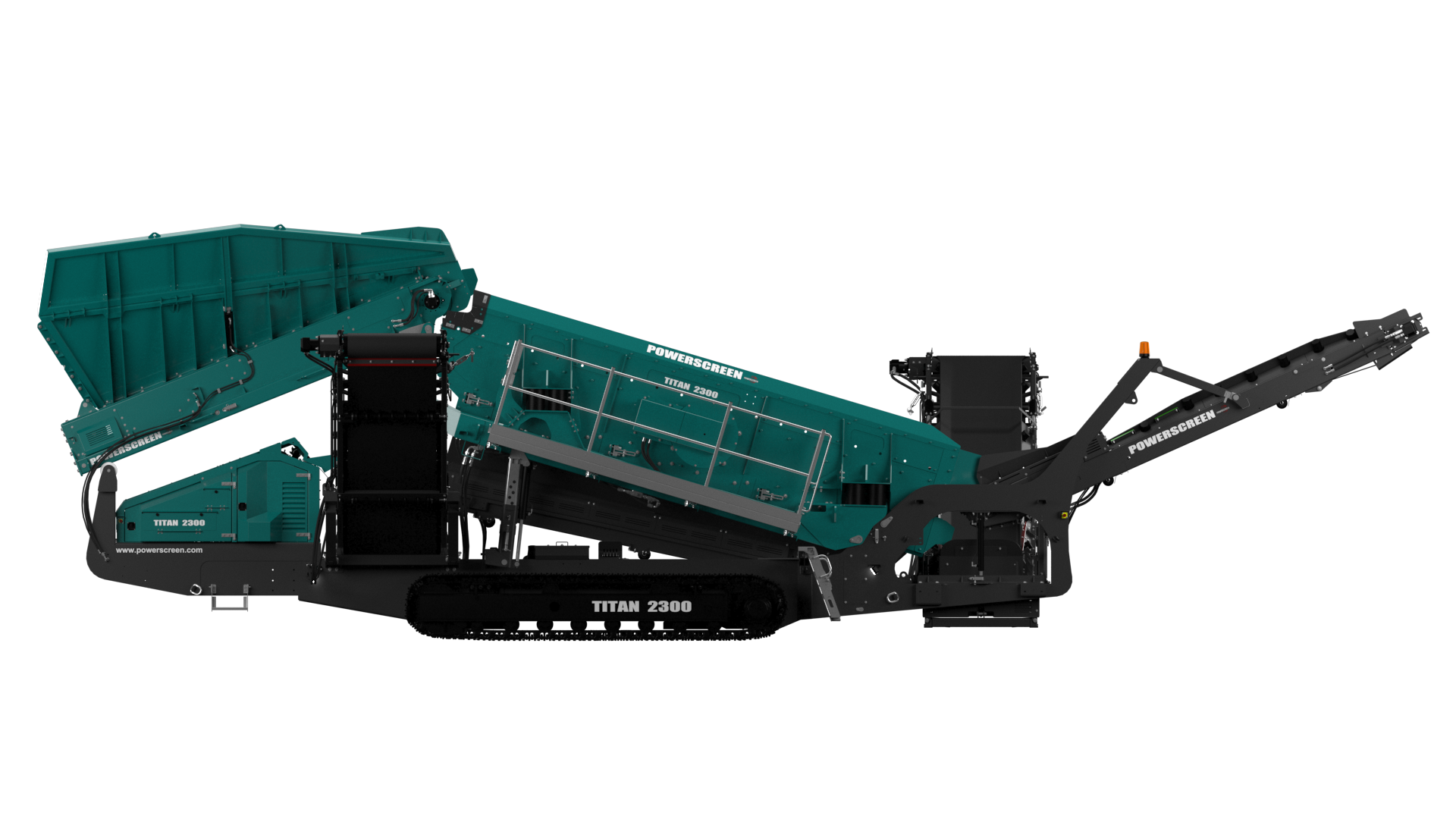

Titan 2300

The Titan 2300 is a mobile scalper that has been designed for a range of screening applications. Capable of a 2 way and 3 way material split, this machine can be operated as a standalone unit or as a secondary screen.

The highly aggressive single shaft screenbox can output up to 700tph (771 US tph) depending on the application.

go back

go back