Conveying

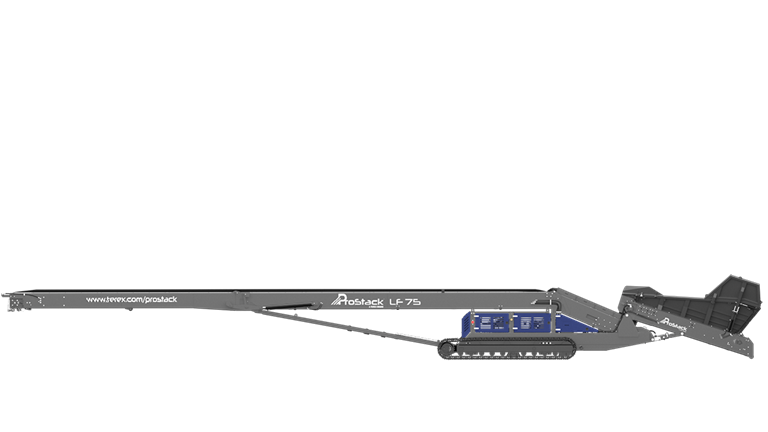

LF 75

The ProStack LF 75 is a Low Level Radial Tracked Feeder Conveyor with a belt length of 22.5m and a belt width of 1.2m. A rotating undercarriage gives this conveyor increased versatility. With unrivalled portability and durability the LF 75 can operate in a wide variety of working environments. This conveyor can be integrated with crushers and screeners to stockpile material directly from the source. Site traffic will also be reduced and it will remove the need for double handling of material.

go back

go back