Specifications

HOPPER / FEEDER

2.3m3 (3yd3) Hopper capacity

Two stage 'Tine' grizzly feeder as standard

26mm (1") Nominal spacing

IMPACT CRUSHER

860mm (34") X 610mm (24") Crusher inlet

830mm (33") Wide x860mm (34") diameter rotor

2 High / 2 low configuration as standard

Max OSS - 120mm (4.75") upper 55mm (2.25") lower

Min OSS - 40mm (1.4") upper 20mm (0.75") lower

Hydraulic adjust and hydraulic overload protection as standard

Rotor speed: 700-930rpm (32-40m/s tip speed)

OUTPUT POTENTIAL

Up to 250 tph / 275 US tph

POWERUNIT

Tier 3: CAT C7.1 186kW/250Hp

Tier 4: 202kW/ 275Hp CAT C7.1 engine

Direct drive to crusher via clutch and V belts

CONVEYORS

900mm (36") Wide product conveyor

Product conveyor discharge height: 3420mm (10'8")

GENERAL

Intuitive colour screen control panel

TRANSPORT

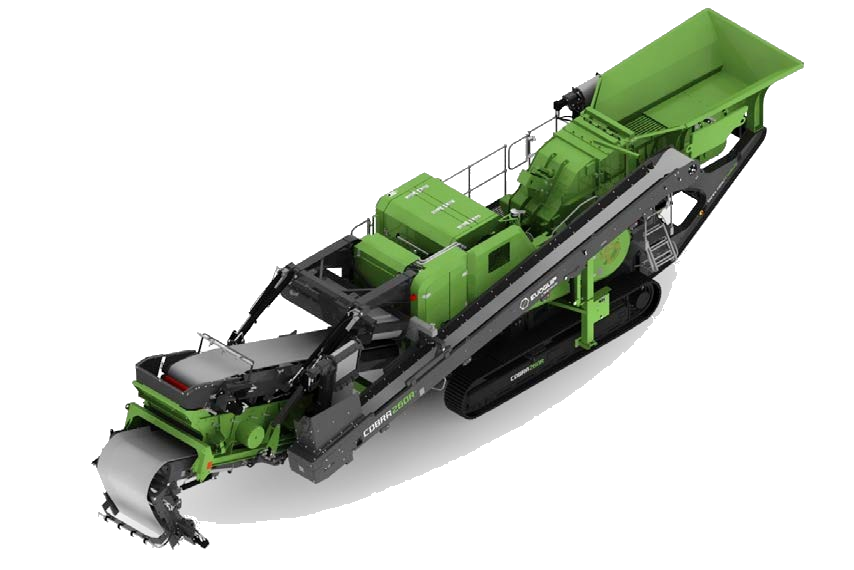

Track Unit: L 12.05m (39'6") W 2.5m (8'2") H 3.2m (10'6")

Weight (with Side Conveyor & Magnet)

27,000Kgs (59,525lbs)

Length 13.4m with non-folding conveyor

Length is 12.05m with optional folding conveyor

Features

Output potential 250 tph (275 US tph)

Suitable for a variety of feed materials

Ideal for recycling & demolition applications

Replaceable tine bar cartridge style grizzly feeder

Load management system to control feeder speed

Proven Terex impact crusher with hydraulic overload protection, 4 bar rotor & twin aprons

Crusher speed variation through user friendly PLC control system

Fully independent under crusher vibrating pan feeder (Optional)

Latest generation power unit that meets EU Stage IV / US Tier 4F emissions legislation

HPTO clutch & highly fuel efficient direct drive system

Modular conveyor with raise/lower facility to aid clearance of rebar

Overband magnet (Optional)

Options

The EvoQuip Cobra 260R Horizontal Shaft Impactor, is a highly compact tracked crusher designed to offer both excellent reduction & high consistency of product yield. The EvoQuip Cobra 260R is designed mainly for the recycling & demolition markets & is an ideal contractor machine due to its compact design & mobility.